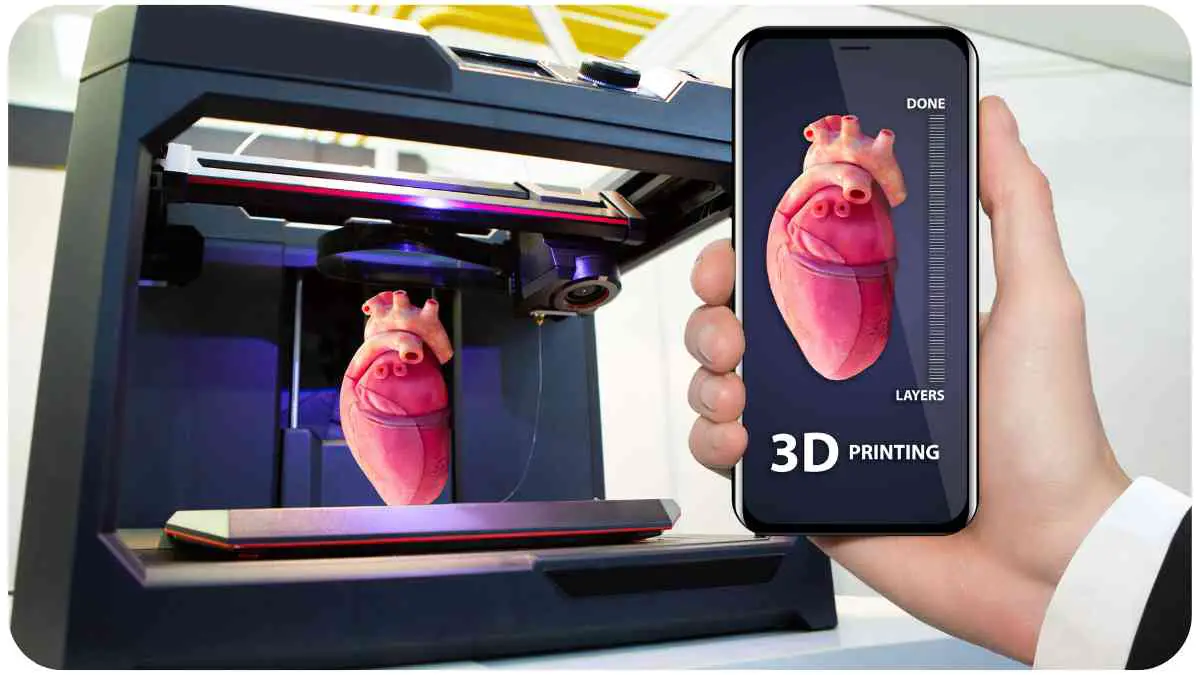

3D printing has evolved from a niche technology to a transformative tool, impacting various industries, including art. For artists, it opens up new possibilities for creating intricate and detailed pieces that were once challenging to produce.

However, before diving into the world of 3D printing, it’s crucial to understand the associated costs.

Artists are drawn to 3D printing for its ability to turn digital designs into tangible, three-dimensional objects. The technology allows for the creation of complex shapes and structures, giving artists the freedom to explore innovative concepts.

While the creative possibilities are vast, artists need to weigh the cost-effectiveness of integrating 3D printing into their artistic process.

| Takeaway |

|---|

| 3D printing costs vary based on printer type, materials, labor, and recurring expenses. |

| Initial investments include the 3D printer, materials, labor, software, maintenance, and electricity. |

| Printer costs range from $200 to $10,000, with industrial printers exceeding $100,000. |

| Materials like PLA, ABS, and specialty filaments contribute to printing expenses. |

| Labor costs involve setup, design, and post-processing, impacting overall project expenses. |

| Recurring costs include maintenance, electricity, and ongoing material expenses. |

| Material costs range from $20 to $100 per kilogram, depending on the type. |

| Different 3D printing technologies, such as FDM, SLA, SLS, MJF, and DLP, have varying costs. |

| Post-processing costs, including curing, cleaning, and finishing, add to the overall expense. |

| Hidden costs, such as print failures, machine depreciation, and facility expenses, impact budgets. |

| The learning curve, quality control, and pursuit of perfection contribute to associated costs. |

| Minimizing waste, optimizing design, and choosing cost-effective materials help reduce expenses. |

| The economics of scale play a role, with bulk printing and material purchasing influencing costs. |

| External resources, such as articles from Raise3D Academy and RapidDirect, offer valuable insights. |

| Frequently asked questions address basic printer costs, recurring expenses, cost-effectiveness, and optimization. |

2. Initial Costs of 3D Printing

Investing in 3D printing involves several initial expenses that artists should consider. Let’s break down these costs:

Exploring the safety of 3D printing pens is crucial for artists. What you need to know about their safety measures and potential risks ensures a secure creative process.

2.1 3D Printer Options

Choosing a 3D printer is a pivotal decision that significantly influences the overall cost. Here’s a breakdown of different printer options:

| Type | Average Price Range | Upper Limit |

|---|---|---|

| Entry-Level | $200 – $500 | $1,000 |

| Hobbyist | $500 – $3,000 | $5,000 |

| Professional | $3,000 – $10,000 | $20,000 |

| Industrial | $10,000 – $100,000 | >$500,000 |

2.2 Materials and Their Costs

The choice of materials for 3D printing also contributes significantly to the overall expenses. Here’s a breakdown of material costs:

| Material | Price Range per Kilogram |

|---|---|

| PLA (Polylactic Acid) | $20 – $30 |

| ABS (Acrylonitrile Butadiene Styrene) | $25 – $40 |

| PETG (Polyethylene Terephthalate Glycol) | $22 – $35 |

| Specialty Composites | $100 – $200 |

2.3 Labor and Time Investment

Beyond the upfront costs, artists should consider the labor involved in 3D printing. Setting up prints, designing models, and post-processing all require time and expertise. Labor costs can range from $15 to $75 per hour, depending on the level of expertise.

Crafting a perfect scrapbook relies on choosing the right supplies. Discover expert tips and essential tools to elevate your scrapbooking projects effortlessly.

2.4 Software Expenses

While some 3D printing software options are free, advanced design and printing suites can cost up to $1,500. Artists need to factor in software expenses when evaluating the overall cost of 3D printing.

2.5 Maintenance and Upkeep

Printers require regular maintenance to ensure optimal performance. This includes tasks such as cleaning, replacing parts, and calibrating the printer. Maintenance costs can range from $50 to $500 annually.

2.6 Electricity Consumption

Running 3D printers for extended periods incurs electricity costs. The average electricity consumption per hour varies by printer type, ranging from 50 watts to 150 watts. At an average rate of $0.13 per kWh, electricity costs can range from $0.0065 to $0.065 per hour.

3. How Much Does a 3D Printer Cost?

The cost of a 3D printer depends on its features, quality, and intended use. Here’s a breakdown of different categories of 3D printers and their average costs:

3.1 Entry-Level 3D Printer

Ideal for beginners, these printers are often limited in features and print quality.

| Type of 3D Printer | Average Price | Upper Limit |

|---|---|---|

| Entry-Level | $200 – $500 | $1,000 |

3.2 Hobbyist 3D Printer

Offers better quality and more features than entry-level options.

| Type of 3D Printer | Average Price | Upper Limit |

|---|---|---|

| Hobbyist | $500 – $3,000 | $5,000 |

3.3 Professional 3D Printer

Ideal for professionals and small businesses, offering high-quality prints and advanced features.

| Type of 3D Printer | Average Price | Upper Limit |

|---|---|---|

| Professional | $3,000 – $10,000 | $20,000 |

3.4 Industrial 3D Printer

Top-of-the-line machines used by large businesses and manufacturing units.

| Type of 3D Printer | Average Price | Upper Limit |

|---|---|---|

| Industrial | $10,000 – $100,000 | Can exceed $500,000 |

Raise3D Professional Printers

Raise3D Pro3 Series, including two models: Pro3 starting from $5,599.00 and Pro3 Plus starting from $7,599.00.

Transform your space with custom furniture. This comprehensive guide provides valuable insights into design, construction, and crafting techniques for unique and personalized pieces.

3.5 Understanding 3D Printing Technologies and Their Costs

3.5.1 Fused Deposition Modeling (FDM)

FDM is one of the most accessible forms of 3D printing technology. It’s cost-effective, with entry-level printers starting at a few hundred dollars and higher-end models reaching thousands.

3.5.2 Stereolithography (SLA)

SLA, a resin-based 3D printing technology, offers high resolution and quality. Entry costs for SLA printers are higher compared to FDM, often ranging into several thousand dollars.

3.5.3 Selective Laser Sintering (SLS)

SLS uses a powerful laser to fuse polymer powder into a solid structure. The technology’s strength and durability make it suitable for functional prototypes. However, SLS 3D printers are in a higher price bracket, often used by professional services and businesses with a considerable budget.

3.5.4 MultiJet Fusion (MJF)

Developed by HP, MJF is known for its speed and precision detail capabilities. As a cutting-edge technology, MJF printers and their maintenance costs are higher, typically targeting industrial use with a significant investment required.

3.5.5 Digital Light Processing (DLP)

Similar to SLA, DLP uses light to cure resin. However, DLP employs a digital light projector screen to flash a single image of each layer simultaneously, making it faster than SLA in some cases. The costs for DLP technology are comparable to SLA, increasing with the printer’s size and complexity.

3.6 Peripherals and Setup Requirements

Beyond the printer itself, successful 3D printing operations necessitate various peripherals and setup investments. For resin-based printers like SLA and DLP, a curing station is vital, often adding several hundred dollars to the initial cost. Maintaining a consistent print environment may also result in expenses such as dedicated space and electricity supply, adding to overhead costs.

For pottery enthusiasts facing equipment issues, fixing a broken pottery wheel is essential. This step-by-step guide ensures a smooth repair process, allowing artists to continue creating pottery effortlessly.

3.7 Software for 3D Printing

Slicing software, essential for translating 3D models into printable instructions, plays a crucial role in 3D printing. Options range from free slicers like Cura to advanced, feature-rich suites that cater to professionals, which can cost several hundred dollars.

4. Recurring Expenses in 3D Printing

Understanding the recurring expenses of 3D printing is vital for hobbyists and professionals alike. Among these, the cost of materials stands out as a significant factor.

4.1 What is the Cost of 3D Printing Materials?

Figuring out the costs associated with 3D printing materials is fundamental when estimating the budget for any 3D printing project. The price of materials can dictate profit margins, project feasibility, and even design choices.

4.1.1 Filament Costs: From PLA to Specialty Composites

Filaments are a popular choice for many 3D printer enthusiasts, especially within Fused Deposition Modeling (FDM) printing technology. The prices for these filaments vary, primarily depending on the type and quality:

| Type of Filament | Average Price per Kilogram |

|---|---|

| PLA (Polylactic Acid) | $20 – $30 |

| ABS (Acrylonitrile Butadiene Styrene) | $25 – $40 |

| PETG (Polyethylene Terephthalate Glycol) | $22 – $35 |

| Specialty Composites | $100 – $200 |

4.1.2 Resin Costs: Standard vs. Specialized Formulations

For resin-based printers like SLA and DLP, liquid resins are used, and their costs vary:

| Type of Resin | Average Price per Kilogram |

|---|---|

| Standard Resins | $50 – $70 |

| Specialized Resins | $80 – $200 |

4.1.3 Post-Curing Costs for Resin Printing

Resin printing technologies require a post-curing process. Here are key points to consider:

- Post-Curing Equipment: Ranging from basic UV curing lamps ($30-$50) to advanced curing stations (several hundred dollars).

- Materials for Post-Curing: Isopropyl alcohol (IPA) or alternative washing solutions ($20-$60 per gallon).

Explore the rich history of sculpting with insights into the evolution of sculpture. From ancient techniques to modern innovations, this article provides a captivating journey through the world of sculptural art.

4.1.4 Metal Powders and Other Advanced Materials

Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) 3D printers use metal powders. These materials represent a significant jump in costs due to their applications in industrial and high-performance contexts:

| Type of Material | Average Price per Kilogram |

|---|---|

| Stainless Steel Powders | $100 – $300 |

| Titanium Powders | $300 – $600 |

| Other Advanced Materials | Exceed $600 |

4.2 Electricity Consumption of 3D Printers

The energy consumption of 3D printers is an often overlooked aspect of the overall cost. The 3D printer model, power requirements, and duration of use affect the energy costs.

On average, a 3D printer consumes about 50 watts (0.05 kWh) to 500 watts (0.5 kWh) per hour. At the average US electricity rate of $0.13 per kWh, the cost can range from $0.0065 to $0.065 per hour. For a printing job lasting 10 hours, the electricity costs could range from $0.065 to $0.65.

| 3D Printer Type | Average Watts per Hour | Low Print Time (2 hours) | Average Print Time (10 hours) | High Print Time (50 hours) |

|---|---|---|---|---|

| FDM | 50-100W | $0.013 – $0.065 | $0.065 – $0.65 | $0.325 – $3.25 |

| SLA | 30-50W | $0.008 – $0.04 | $0.04 – $0.4 | $0.2 – $2 |

| SLS | 100-150W | $0.026 – $0.065 | $0.13 – $0.65 | $0.65 – $3.25 |

5. Maintenance and Service of 3D Printers

Maintaining a 3D printer is crucial for ensuring its longevity and reliability. Regular upkeep prevents issues that can lead to diminished print quality or printer downtime. Here are the typical maintenance tasks and their associated costs:

| Maintenance Task | Cost Range |

|---|---|

| Replacing the build plate | $25 – $100 |

| Changing the nozzle | $10 – $50 |

| Lubricating moving parts | Negligible cost |

| Updating software | Usually free |

| Calibration checks | Variable, may incur fees for professional services |

A rough estimate for monthly 3D printer maintenance costs can range from $20 to $200, scaling with the printer’s complexity and frequency of use.

6. Labor Costs in 3D Printing Operations

A significant portion of 3D printing costs is associated with labor—the skilled operation of the machinery and the intricate art of design. Labor costs vary depending on factors like expertise and complexity of the design.

6.1 Machine Operation

- Hourly Wage for Machine Operation: In the US, machine operators may command hourly wages ranging from $15 to $25.

6.2 3D Design

- Hourly Wage for 3D Design: Specialized 3D design work can elevate labor costs to $30-$60 per hour.

7. How to Calculate the Price of a 3D Print?

Understanding the price of a 3D print is essential for hobbyists and businesses alike. The calculation involves more than simply assessing the amount of material used. Several factors come into play, each as crucial as the next in determining the final price tag.

7.1 Model Volume and Complexity

- Model Volume and Time to Print: Larger and more intricate designs may require more material and time, impacting costs.

7.2 Material Costs

- Material Selection: Different materials have varying costs per gram, influencing the overall cost of the print.

- Infill and Density: Adjusting the infill percentage and pattern can optimize the balance between strength and material volume.

7.3 Post-Processing Costs

- Support Removal: Depending on complexity, support removal can range from negligible to a substantial part of post-processing costs.

- Sanding, Polishing, Painting, Sealing, Assembly: Each post-processing step adds to the overall cost, depending on the desired finish and complexity.

8. The Impact of Model Complexity on Printing Costs

Model complexity can significantly affect printing costs beyond the raw material usage. It’s not merely the sophistication of the design but also how it translates to the printing process.

8.1 Design Considerations

- Support Structures: Intricate details and overhangs may require support structures, using additional materials and post-processing efforts.

- Printer Capabilities: The type of 3D printer used influences the level of detail achievable and affects the design’s complexity.

8.2 Print Failure Risk

- Learning Curve: With complexity comes an increased likelihood of print failures, adding to the learning curve costs for those new to 3D printing.

9. Volume and Material Usage Estimations

The volume of your 3D model and the material you select are tangible aspects when calculating costs. Estimations usually start with the calculation of the model’s volume, considering the density of the chosen material and any infill patterns used during printing.

9.1 Material Selection

- Material Type: From standard plastics like ABS and PLA to specialty filaments and resin materials, each has a price per gram that must be factored into the cost calculation.

9.2 Infill and Density

- Infill Percentage and Pattern: 3D prints don’t have to be solid; many are printed with an internal grid-like structure to save on material without compromising strength. The percentage of infill can affect material usage and cost.

9.3 Waste and Supports

- Efficient Design: Minimizing unnecessary bulk in design can decrease material usage and print time.

- Supports: Consider additional material necessary for support or material that becomes waste. Efficient design can minimize this, improving cost-effectiveness.

10. Post-Processing: Types and Costs

Post-processing isn’t just a cosmetic choice; it’s often a necessity for achieving the desired final product. The type of post-processing needed can depend on the end-use of the product, whether it’s for functional prototypes, display models, or end-use parts.

10.1 DIY vs. Professional Finishing Services

- DIY Post-Processing: Saves on labor costs but requires time investment and specific skills.

- Professional Services: More expensive but brings a level of finish and time efficiency crucial for commercial projects.

10.2 Hidden Costs in 3D Printing

- Print Failures: Squanders raw materials, electricity, and machine time, impacting overall production efficiency.

- Machine Depreciation: Influences long-term profitability and replacement strategies.

11. Facility Costs: The Price of Space and Environment

The environment where a 3D printer operates can contribute to overall costs. Whether it’s a dedicated printing room or a multi-purpose space, the conditions necessary for optimal printing—like temperature and humidity control—can increase overhead costs for a 3D printing business.

11.1 Optimizing Space

- Dedicated Printing Room: Costs associated with a dedicated space for 3D printing, ensuring optimal conditions for printing.

- Temperature and Humidity Control: The need for climate control measures to maintain consistent printing conditions.

12. Minimizing Waste for Cost-Effective Operations

A diligent approach to waste management is crucial in 3D printing to reduce costs and enhance efficiency.

12.1 Strategies for Waste Reduction

- Optimize Design: Employing software to refine designs and remove unnecessary bulk can decrease material usage and print time.

- Printer Maintenance: Regular maintenance can mitigate the risk of print failures, ensuring consistent print quality and material efficiency.

12.2 Intellectual Property Concerns and Financial Consequences

- Protecting Intellectual Property: Costs associated with securing intellectual property rights to prevent unauthorized use and potential financial losses.

13. Machine Breakdowns: An Interruption with a Price Tag

A 3D printer in disrepair halts production and may require costly repairs or replacements. Such interruptions also affect delivery timelines, potentially impacting customer satisfaction and retention.

13.1 Repair Costs

- Cost of Repairs or Replacements: Unforeseen breakdowns can lead to unexpected costs for repairing or replacing parts, impacting the overall budget.

14. The Learning Curve and Associated Costs

Proficiency in handling 3D printing technology doesn’t come overnight. Training employees or spending time learning the intricacies of 3D printing software and hardware incurs costs in terms of both time and potential for error during the learning process.

14.1 Training Costs

- Employee Training: Costs associated with training employees to operate and maintain 3D printers efficiently.

- Learning Curve: The time and potential errors during the learning curve can impact initial production efficiency.

15. Quality Control and the Cost of Perfection

Striving for high fidelity and precision in prints can escalate costs. As print quality increases, so does the scrutiny on the printing process, often necessitating more expensive materials, finer resolution settings, and potentially slower print speeds to achieve the desired outcome.

15.1 Balancing Quality and Costs

- Material Quality vs. Cost: Finding the right balance between using high-quality materials and managing costs.

- Print Settings for Optimal Quality: Adjusting settings for optimal quality without significantly increasing costs.

Conclusion

This guide has covered various aspects of the economics of 3D printing, from initial costs to hidden expenses. Understanding these factors is crucial for businesses and hobbyists to ensure that venturing into 3D printing technology is efficient and economical.

In the next section, we’ll wrap up the article, summarizing key points and offering a closing perspective.

Further Reading

- Raise3D Academy: 3D Printing Cost and Printer Price: This comprehensive guide on Raise3D’s Academy provides insights into both the cost of 3D printing and the prices of 3D printers. It covers various factors influencing costs, helping readers understand the expenses involved in the 3D printing process.

- Artist-3D: A Comprehensive Guide to Understanding 3D Printing Costs: Artist-3D offers an in-depth guide, breaking down the costs associated with 3D printing. From initial investments to recurring expenses, this resource provides valuable information for artists and enthusiasts looking to delve into the world of 3D printing.

- RapidDirect: 3D Printing Service Cost – Factors Determining the Cost: This Medium article by RapidDirect explores the factors that contribute to the cost of 3D printing services. It delves into the intricacies of service costs, offering a detailed understanding of how different elements impact the overall expenses in professional 3D printing.

FAQs

How much does a basic 3D printer cost?

The cost of a basic 3D printer can vary widely, ranging from $200 to $500 for entry-level models. Factors such as features, print quality, and brand influence the price.

What are the recurring expenses in 3D printing?

Recurring expenses in 3D printing include material costs, electricity consumption, maintenance, labor, and software costs. These ongoing expenses contribute to the overall cost of 3D printing projects.

Is 3D printing cost-effective for small businesses?

Yes, 3D printing can be cost-effective for small businesses, especially when producing prototypes, custom parts, or small batches of products. However, factors like material choice and printer selection play a crucial role in determining overall cost-effectiveness.

How can I reduce the hidden costs in 3D printing?

To reduce hidden costs in 3D printing, focus on minimizing material waste, optimizing design, and investing in regular printer maintenance. Additionally, consider the economic benefits of bulk printing and efficient material purchasing.

What are the key considerations for optimizing 3D print settings?

Optimizing 3D print settings involves adjusting layer height, infill percentage, support usage, and print speed. Balancing these factors helps achieve cost efficiency without compromising print quality.

Hellen James is the creator of Unified Crafts and has been crafting since she was a kid accompanied by her mom to the craft store, where she was free to choose whatever ignited her imagination.